Water Jet Cutting and Milling

We exclusively use multi-axis NC machining centres for machining each thermal insulation plate. Depending on specifications and requirements, we use water jet cutting or mechanical processing techniques.

Water jet machining

With water jet machining, it is possible to produce any desired contour and, for example, to design edges with small radii. Plates with thicknesses up to 30 mm can be cut with smooth edges and no micro-cracks. Since the absence of micro-cracks prevents oxygen from penetrating into the interior of the plate, the service life of our plates is significantly increased compared to that of plates produced using non-optimised cutting techniques.

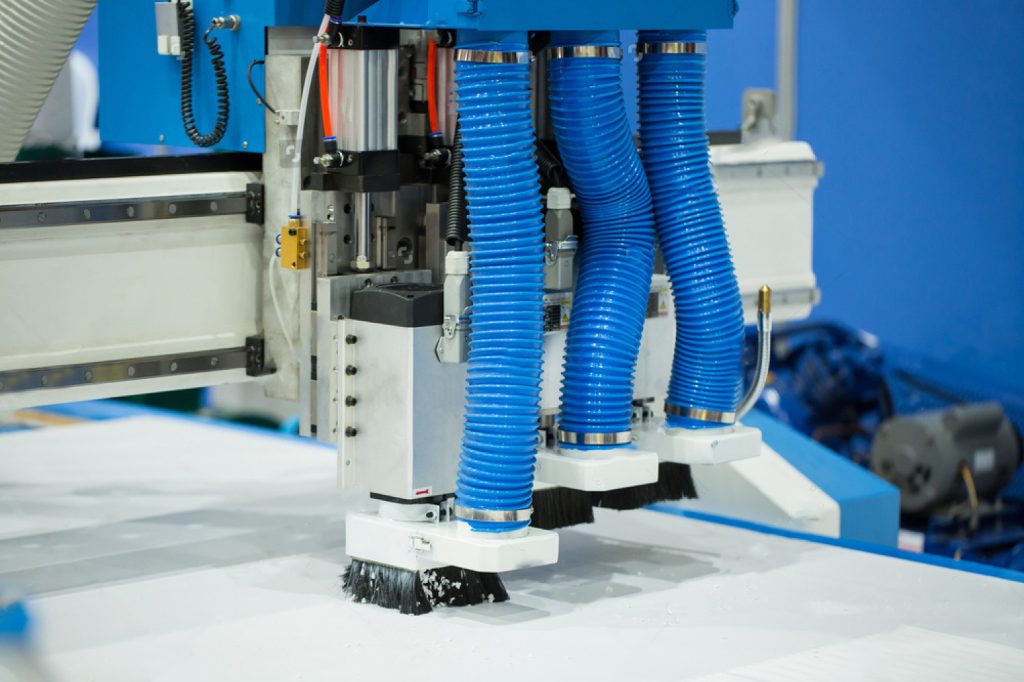

Mechanical machining

The milling technique is applied when plates with grooves or countersunk holes are required. A 5-axis NC milling machine provides the platform for this purpose. As with water-jet cutting, the machining conditions are optimised to ensure smooth edges and prevent micro-cracks.